The Importance of Mixing Epoxy Correctly

By Roderick Kabel

Epoxy ratio mixing 101 – The proper measuring and mixing of epoxy and perspective ratios. This is a step that sometimes gets glossed over, but it’s important to know how to do it right for a flawless final epoxy project.

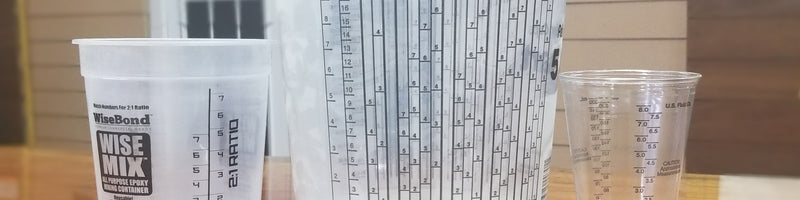

Epoxy kits such as WiseBond™ kits come with a resin (A) and a hardener (B). Epoxy, whether a 1:1, 2:1, or another ratio, should be precisely measured like a recipe in the kitchen. WiseBond™ sells a 2:1 ratio DEEP POUR™, a 1:1 ratio Bar & Table Top epoxy, and a 1:1 ratio Quick Set epoxy.

A 2:1 ratio means 2 parts of A resin, and 1 part of B hardener are mixed together. A 1:1 ratio means 1 part of A resin and 1 part of B hardener are mixed together. These specific ratios mixed together create a very specific chemical reaction (a molecular handshake) which causes the combined epoxy cure solid. A hard epoxy cure is 100% dependent on properly measuring and mixing epoxy.

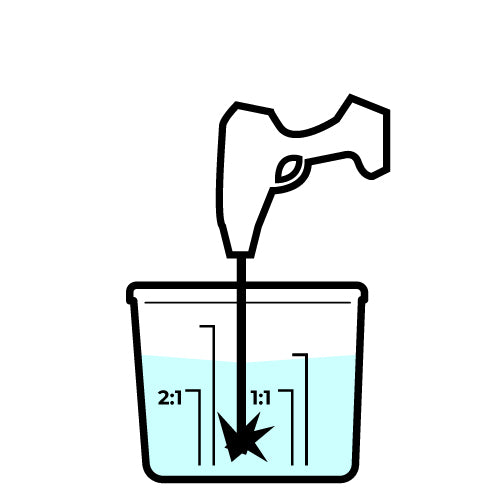

Improperly mixing epoxy is the #1 problem people face. The best method to measure epoxy is by using a clear measuring container with measurements and ratios printed on the outside of the container.

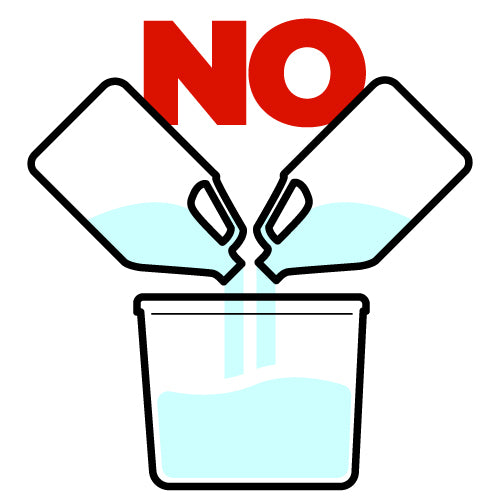

The issue at heart is an assumption on the user’s part. Epoxy users assume that the amount of epoxy in the A and B jugs are accurate enough to mix by. This is true however, getting all of the epoxy out of the jugs is very difficult.

Simply put, the viscosity of epoxy is such that A and B sides drain differently from the jugs and this makes the act of pouring from the jugs and not measuring, a no-no.

We always advocate to NEVER just pour both A and B into the mixing container without measuring proper ratios. Always follow the 1:1 or 2:1 ratio measurement listed on the epoxy kit containers. Be sure to measure by volume, not by weight.

Keep in mind that mixing containers have many different measurements and ratios imprinted on the side of the container. Most any paint store or big box outlet will have these to easily purchase.

If your epoxy project requires more epoxy than the chosen mixing container can hold, simply mix in smaller batches, then dump each batch into a larger, clean holding bucket for final mixing.

After each smaller batch is mixed, completely scrape down the container sides and bottom and continue with your next batch in the same container. (Cheap rubber spatulas work great!) After all your epoxy is in your larger holding bucket, give it another mix for a few minutes to assure everything in cohesive before pouring.

Why is this so important?

If epoxy is not properly mixed there can and will be serious problems during the cure. If mixing ratios are slightly off, this can cause a hot spot. A hot spot is when there is unmixed A-side or B-side floating around in the final pour. This can initiate a premature exothermic reaction too early in the cure time, and set off a chain reaction that can cause drastic cracking. Or, the epoxy just won’t cure hard at all. Either way, this is a hard lesson to learn.

MIXING EPOXY RESINS

-

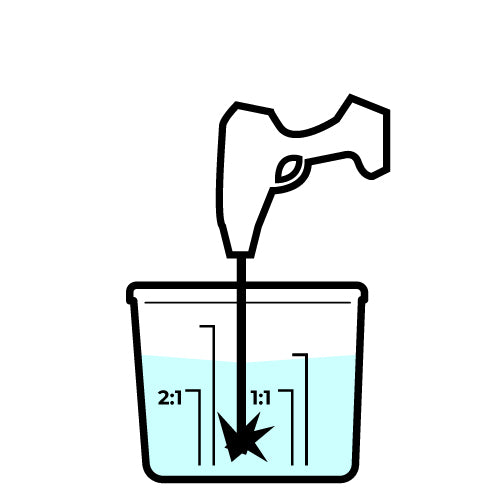

After the two parts are poured at the correct ratio, mix them together thoroughly for a full 6 - 8 minutes for 2:1 and 3-5 minutes for Table Top epoxy. Use a clean mixing stick or paddle on a drill, mix longer for larger quantities.

-

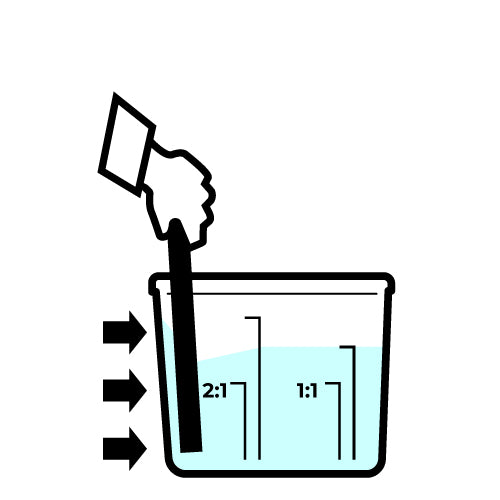

Be sure to scrape the sides, corners, and bottom of the container several times during mixing. This will ensure that all the A resin and B hardener are thoroughly mixed.

- Add any colorants at this point and mix until you've acheived the desired saturation.

-

If the mixture doesn't have a single consistency (streaks or swirls remain) continue mixing until fully blended and a homogenous mixture appears.

- Begin pouring the epoxy immediately. The larger the quantity of mixed epoxy in the mixing container, the faster the pot-life and working time are.

SAFETY

Make sure to have the proper PPE, tools and safety equipment for using and handling epoxy resins.

- Eye Protection

- Reusable Rubber Gloves or Disposable Latex

- Clean Mixing Cups with Measurements

- Clean Mixing Sticks and or Paddles

- Rubber Spatula(s)

My counter top is soft even after two months and coffee cups are leaving an indentation. What’s the fix? Am I going to have to completely sand it down and start over? I’m assuming that I didn’t get the correct hardener to epoxy ratio.