500 to $1200 depending on sq. ft.

Our Water-Based Epoxy Resin Flake Floor Kit is perfect for the DIY homeowner. It comes with a pre-tinted epoxy base coat, flake floor chips, and your choice of a urethane top coat - enough for 2 coats. Applications range from concrete garage floors, residential interiors, small warehouses, bars, automotive showrooms, or anywhere that an exceedingly resilient interior concrete flake floor is desired.

This complete epoxy garage floor color flake kit (also referred to as color chips, or epoxy paint chips) adds little explosions of color creating a beautiful custom floor!

Shoreline 1/4" Garage Flake Floor Kit Includes:

Moisture Barrier, Crack Filler, Cleaner/Etcher, Top Coats, and Flakes also sold separately for custom design floors. View Here

NOTE: For larger Sq. Ft. coverage selections, additional product included.

Coverage:

Shoreline Flake Color Scheme:

Top-Coat Options: 1-Gallon Water-Based Urethane Gloss or Satin finish, or 1-Gallon Solvent-Based High-Gloss Urethane. Top coat coverage per 250 sq. ft. as a 1 coat coverage whereas a second coat is optional depending on desired smoothness of top coat texture.

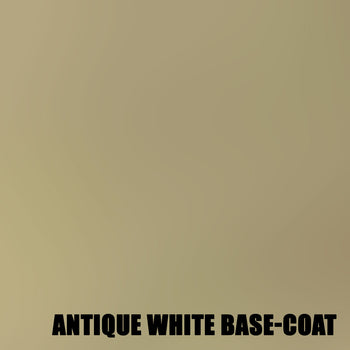

The pre-tinted base-coat floor epoxy is a 2 component 52% solids, low VOC floor hard coating. It is a durable-colored base layer for both new and old interior concrete floors; a primer coat; and a binder for epoxy flakes. The high loading of the base coat pigment achieves the preferred substrate tint uniformity.

This base coat floor epoxy creates the highest balance of strength, flexibility, and chemical resistance, all in a low odor, low VOC formulation. Unlike most all 100% solids epoxies, it has remarkable properties related to moisture:

Delivered in this kit are more flake product than is needed. You’ll have all you need for a 100% broadcast flake coverage.

Besides the obvious advantages of colorful custom flake color combinations like this one, color flakes also provide some sound deadening qualities and hide sub-surface imperfections in your concrete. This means concrete patch work and spider cracks are less likely to show through the epoxy coating.

In addition, vinyl color floor flakes such as these are also flexible and strong. When applied to full refusal, they will add a minimum of 5 mils of thickness to your floor, improving both the durability and impact resistance of the surface.

Lastly, unlike epoxy alone, the garage floor flakes are U.V. stable. If you apply them to full refusal on an epoxy coating and then clear coat with a U.V. stable Urethane, you will never experience ambering (yellow tint) from exposure to direct or strong indirect sunlight.

Water-Based Polyurethane: Clear finish topcoat is available in gloss or satin finishes provides the durability of a solvent base system with the ease and safety of a low VOC (73 g/L) water base system. More user friendly than a polyaspartic and can be used on interior concrete floors. Read More Here.

Solvent-Based Polyurethane: Clear finish topcoat is available in gloss provides durability of a polyaspartic. The high-gloss clear top coat generates the premier balance of strength, added UV stability, flexibility, chemical and scratch resistance that is both user-friendly and extremely durable. Read More Here.

Once your kit is purchased be sure to read our Pre Prep and Flake application instrustions. These tutorials will be on the emailed receipt and sent to the email you use during the checkout process.

NOTE: If you live in a more humid climate, an area where there’s a lot of rain, or just need protection against moisture, in addition to this floor kit, you may also want to purchase our Moisture Barrier & Vapor Blocker from our Single Items store.

Pour at temperatures between 50°F- 90°F with low humidity in a dust free environment. Allow 24 hours for initial cure. Wait 3 days for a full hard cure.

THOROUGH EPOXY FLAKE FLOOR APPLICATION PROCESS

NOTE: Do NOT skip prepping your garage floor properly! This is the most important part of the application to ensure a good bond. Mechanically grinding the surface of your garage floor is a must if your garage floor has oil stains, cracks, dirt, mold, mildew, or moisture stains. Concrete floors with old paint or any type of coating MUST have it completely removed and mechanically ground clean in order to accept the epoxy flake floor system!

The following is a list of tools and supplies that you will need. All of these tools can be easily purchased at Home Depot, Lowes, Menards, Amazon, or your local Hardware store.

We also included optional tools such as 18" rollers. They are not mandatory, but the wider rollers make the application process go much quicker. We highly recommend these if you are covering areas larger than 500 sq. ft.

Why Spiked Shoes? Spiked shoes allow you to walk out onto the coating during installation and for tossing the color flakes. We recommend a pair for each installer.

Why 18" Items? The 18" roller frames, rollers, and paint tray can easily be purchased online. Some home improvement centers carry them. These products greatly improve the speed and ease of applying a garage floor coating.

PART A - CALIFORNIA PROPOSITION 65: This product contains a chemical(s) known to the state of California to cause cancer, birth defects or reproductive harm, which are subject to the requirements of California Proposition 65. FOR MORE INFORMATION GO TO: WWW.P65WARNINGS.CA.GOV.

PART B - CALIFORNIA PROPOSITION 65: This product contains a chemical(s) known to the state of California to cause cancer, birth defects or reproductive harm, which are subject to the requirements of California Proposition 65. FOR MORE INFORMATION GO TO: WWW.P65WARNINGS.CA.GOV.

© 2025 - WiseBond®, A product of DeckWise®, The Ipe Clip® Fastener Company